In competitive industries like grocery, retail, and others, cost-saving solutions like advanced floor finishes are key. These not just enhance aesthetics but also offer significant savings. Read on to discover how the right floor finish technology can

become an investment in your bottom line.

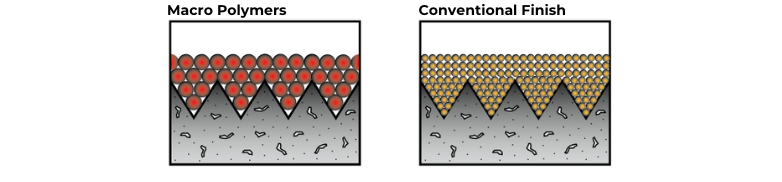

1. Macro Polymers

The strategic use of larger polymers in floor finishes, especially when combined with high solids content and low viscosity, creates a floor finish that forms a more cohesive, more substantial layer atop the floor surface. Molecular largeness ensures

that finish remains on the surface, rather than seeping into the micro-pores of the flooring material. The result is superior coverage, protection, and longevity with fewer applied coats. By reducing the number of coats needed for effective floor

coverage, there's a direct decrease in the amount of time required for application and the quantity of finish used over time, leading to labor and material savings.

In addition to enhancing the protective qualities of the finish, macro polymers also significantly ease the removal process when the time for stripping and reapplication comes, as the finish is less entrenched within the substrate. Streamlining the

removal process similarly translates into labor efficiencies.

Stay Informed: Take Clean Further with Betco

Subscribe to Betco emails to join thousands of other industry professionals and get the most helpful blog posts, the latest news, new product notifications, and invitations to our events conveniently in your inbox!

Yes, Sign Me Up!

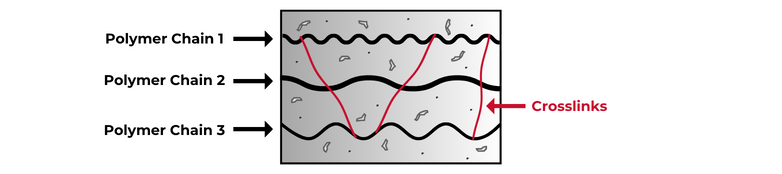

2. Enhanced Crosslinking

Enhanced crosslinking in floor finishes can be compared to transforming loosely woven fabric into a tightly interlocked tapestry. This chemical process forges bonds between polymer chains, akin to interweaving threads more closely and securely together.

The resulting network is a resilient matrix, like a densely woven tapestry that resists pulls and tears. A tightly bound structure grants the floor finish an exceptional ability to withstand the wear from heavy foot and other traffic (such as

shopping carts and forklifts), safeguarding the floor's appearance and integrity over time.

By adjusting the crosslinking density, certain finishes can be optimized for more demanding environments. In addition to the immediate improvement in durability and appearance, reducing the need for frequent refinishing delivers long-term savings.

As a bonus, the less porous nature of a crosslinked finish means spills and stains remain on the surface, making cleanup easier and further protecting the floor beneath.

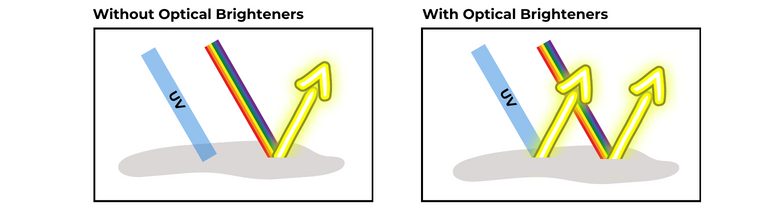

3. Optical Brighteners

Optical brighteners are compounds that capture UV light, which is invisible to the naked eye, and convert it into visible light, effectively emitting a glow that makes the floor surface appear brighter and more vibrant. This process, known as fluorescence,

enhances the overall luminosity of the floor, providing a long-lasting sheen that is aesthetically pleasing and contributes to a more pleasant environment, potentially enhancing the experience of customers or other building occupants.

The enhanced brightness and perceived cleanliness of the floor reduces the frequency with which buffing is required to maintain an attractive appearance. This decreased dependency on buffing extends the lifespan of equipment and contributes to lower

energy consumption, as less power is expended. The reduced need for buffing delivers substantial savings in manpower hours, allowing maintenance staff to focus on other tasks and improving overall operational efficiency.

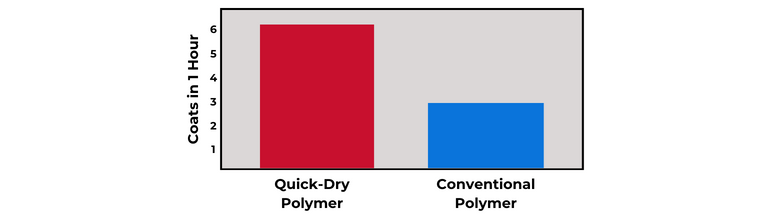

4. Advanced, Quick-Dry Polymers

Some polymers have been engineered to expedite drying and curing processes, with specific molecular weights and structures that enhance the rate at which the carrier medium—often water or solvents—evaporates, and simultaneously accelerate

the bonding process between polymer chains.

This swift formation of a protective layer dramatically reduces the time between coats and finish, as well as the overall time required before a floor area is ready for use again. In environments such as retail spaces, where every minute of accessibility

counts, the ability to quickly return a floor to service can have profound implications for productivity.

The shortened cure times associated with these advanced polymers offer an additional advantage in reducing the vulnerability of the floor finish to damage from premature foot traffic or environmental contaminants, which could otherwise compromise

the finish's integrity.

5. Specialized Wax Blends

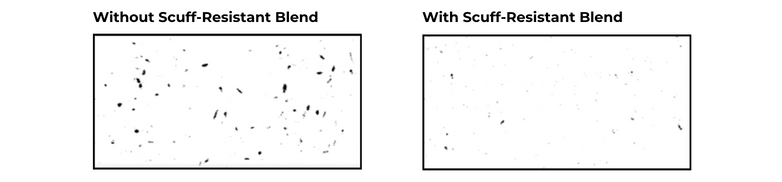

Each wax has unique properties, and strategic blending and incorporation of select waxes with specialized acrylic polymers can result in a finish with particularly excellent black heel mark resistance.

- Waxes with high melting points and durability form a more robust layer to minimize the adhesion and penetration of rubber particles from shoe soles.

- Waxes with a smooth, non-porous finish can reduce the surface area available for frictional contact, diminishing the likelihood of black marks.

- Certain waxes are more seamlessly mixed with other components for even distribution of the protective layer, enhancing the floor's overall resistance to scuffing and marking.

- Effectiveness of waxes in preventing black heel marks also lies in their chemical stability, i.e., whether they break down or become tacky, which can facilitate the transfer of rubber particles to the floor.

Successfully identifying and blending waxes for scuff resistance allows floors retain their clean, polished look for longer periods, reducing the frequency of labor-intensive cleaning processes and the need for specialized cleaning to remove these

unsightly marks.

Conclusion

The intersection of chemistry and floor care technology presents opportunities for operational efficiencies and cost savings. By understanding these features, facilities management, procurement, and operations departments can leverage their knowledge

during product selection, ensuring every square foot of their store contributes positively to the bottom line.

For those interested in elevating their floor care regimen with innovative solutions that deliver significant savings in labor, time, and materials, we invite you to fill out the form below. An expert from our team will reach out to initiate a conversation,

guiding you towards a floor care program that not only meets but exceeds your expectations.