Every floor finish is prone to scruffs, black heel marks, and other smudges that appear from everyday wear and tear. However, some floor finish is formulated to reduce markings, which boosts productivity and saves time. Specific Betco® floor finishes are equipped with Scuff Resistant Technology (SRT), an innovative technology specific to Betco. SRT uses a proprietary technology polymer, wax, plasticizer, and additive package that drastically reduces black heel marks.

A floor finish’s hardness also contributes to resisting scruffs, scratches, and dirt embedment. The higher the hardness percentage, the more durable and long wearing the finish will be, which is especially important on floors with

high traffic.

High traffic can also increase the risk of slips and falls. Slip resistance is the static coefficient of friction between a shoe and a coated floor tile. All Betco floor finishes meet or exceed ASTM D 2047, which contributes to a safer walking

surface. It is the most recognized test method for slip resistance in the United States court of law. To learn more about preventing slips and falls, click here to take our Slip and Fall Prevention module.

2. Maintenance

After the floor finish has been chosen and applied, it is important to maintain it. Burnishing helps the high gloss and semi-gloss floor finish sheens achieve their highest possible shine without needing to perform a full strip and refinish

or scrub and recoat. It also helps floors hold up longer against everyday wear and tear by removing dullness and repairing scratches for an overall cleaner appearance.

The frequency of burnishing is dependent on the type of floor finish. Ultra high-speed floor finishes offer the highest possible gloss on floors but require burnishing 1-7 times per week and usually need to be done with a propane or high-speed

burnisher. This is because these kinds of floor finishes tend to dull quickly and need extra attention to keep them looking their best. Consistent and proper burnishing will reduce additional maintenance and increase the time between top-scrubbing

and stripping. It also reduces the need for a frequent floor restorer, which rejuvenates the floor finish and extends the Life Cycle of Floor Care.

On the other hand, no to low maintenance floor finishes require no burnishing or very little burnishing, potentially once a week or once a month. These floor finishes do not drop in gloss as quickly as they experience wear and tear and therefore

do not need as much maintenance, ideal for facilities with time constraints.

3. Ingredients and Solids

Floor finish is typically made up of the following ingredients.

- Polymers: Commonly called plastics that dictate the main characteristics of the floor finish, like durability and gloss levels

- Resin: A substitute for polymer solids that are usually less expensive, have lower durability, and a poor color

- Plasticizer: Adds to the coatings’ flexibility, gloss, and film formation

- Wax: Provides lubricity to the finish film and allows floor finish to be repaired more easily

- Cosolvent: Helps hold polymers in suspension and aids in film formation

- Additives: Assist in easy application, product storage, and long-term performance of floor finish

- Water: Acts as a medium to evenly distribute all components

After the floor finish is applied, the volatile ingredients—cosolvents and water—will evaporate. The non-volatile ingredients—polymers, waxes, and plasticizers—remain on the floor after the volatiles evaporate.

Usually expressed as a percentage of the total formula, these are referred to as solids, and they provide the protective coating. Floor finishes with over 25% of solids are considered a high solid finish.

High solid floor finishes have more active ingredients, which reduce the number of coats needed during floor finish application and lengthen the time between reapplying floor finish. What may be lesser known is that solids refer to anything that does not evaporate during the curing process of floor finish. There could be unwanted, harmful ingredients included in the formula that causes a floor finish to not perform as expected. Always consult the label for ingredients before

application.

In addition, solid finishes tend to be more expensive due to more additives, like slip resistance, surface textures, and bonding. However, low solid finishes manufactured in recent years are able to perform just as well or even better than

high solid finishes at lesser of a cost. Therefore, comparing solid percentages between finishes should not be the sole factor in deciding a floor finish type.

4. Sustainability

Floor finish that is considered green does not contain zinc, excessive levels of which can pose a threat to environmental and human health. Elevated levels of zinc can cause be harmful to natural ecosystems by inhibiting the uptake of other

essential nutrients by plants. When a floor finish with zinc is stripped, the zinc travels down the drain and eventually ends up in a wastewater treatment plant. It is a difficult material to remove during wastewater treatment and is also

now regulated in wastewater discharge limits.

Metal-interlock finishes use metal ions like zinc to bind together and form a crosslinked network with polymer chains. This technique can help the dried film to be more durable and detergent resistant, which is why most floor finishes commonly

contain zinc.

For more sustainable floor finish options, Betco offers Green Earth® Floor Finish and Green Earth Prelude™ Floor Finish and Sealer,

both of which do not contain zinc or any heavy metals but are still formulated to shine as brilliantly and last as long as conventional finishes. The use of these finishes allows facilities to satisfy green mandates and even attain LEED

certification.

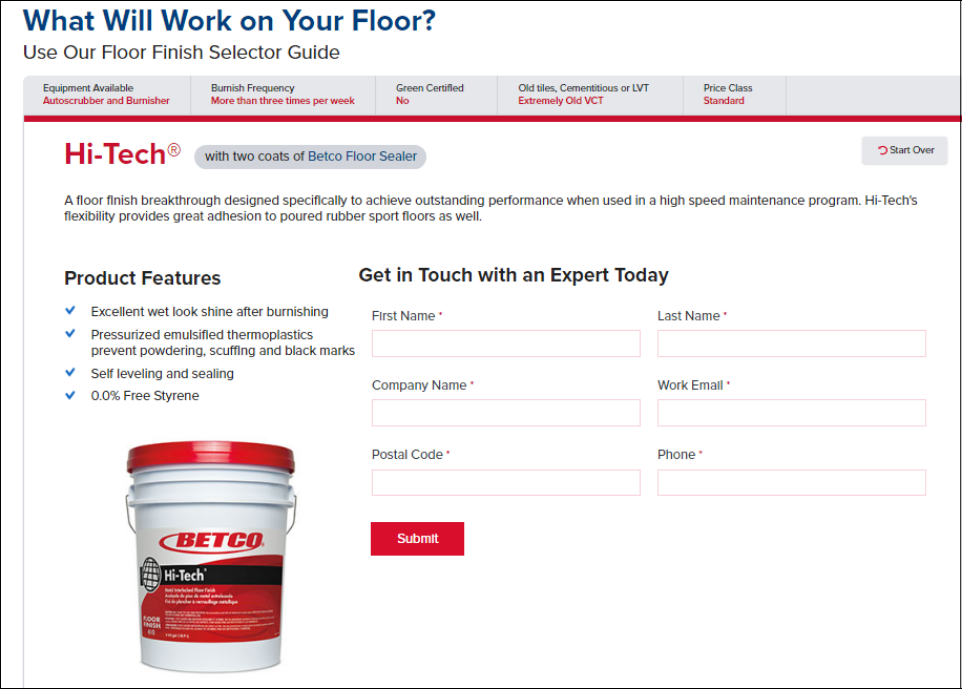

Betco Floor Finish Selector Guide

Betco has a variety of high-quality floor finishes for many floor types that fulfill different performance, maintenance, and sustainability needs. To understand which floor finish will work on your floor, our Floor Finish Selector Guide is

a great tool. Answer a series of questions regarding maintenance, floor type, and budget, and it will recommend the best Betco finish for your floor.

To use the Floor Finish Selector Guide, click here. If you have any questions

about Betco floor finish or any of our floor care programs, please fill out our online contact us form,

or call 1-888-GO-BETCO to speak with a representative today.